In today’s technology-driven world, the microchip industry stands as a critical pillar of innovation and economic strength, making the discussion around revitalizing American microchip manufacturing crucial. The need to AGAIN focus on domestic production has emerged as a focal point in national discussions surrounding economic growth and security. This article delves into the myriad facets of microchip production, addressing its importance, current challenges, innovative strategies, and measuring future success to ensure that America regains its competitive edge in this fundamental sector.

The Importance of Microchip Manufacturing in the Modern Economy

Defining the Role of Microchips in Technology

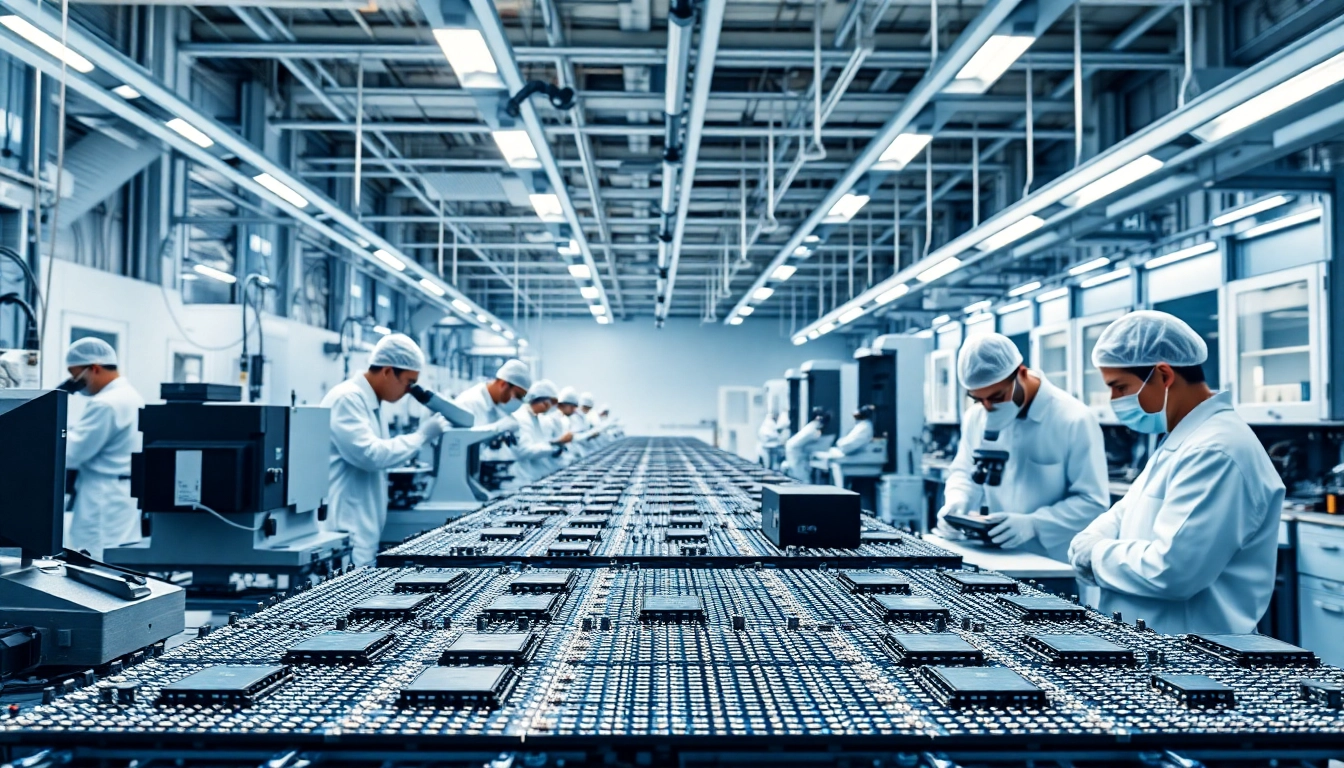

Microchips form the bedrock of nearly all modern technology, from smartphones to industrial machinery. They are intricately woven into the fabric of consumer electronics, computing, telecommunications, and automotive industries. These tiny circuits hold a multitude of functions, including data processing, signal processing, and the automation of systems. The proliferation of the Internet of Things (IoT), artificial intelligence (AI), and machine learning has sparked an exponential increase in demand for microchips, underpinning their remarkable importance in contemporary technological advancements.

Global Competition and Economic Implications

As the microchip field grows, so does global competition, particularly from countries like China, South Korea, and Taiwan. These nations have made significant investments in their manufacturing capabilities, leading to a competitive landscape where the U.S. risks falling behind. The economic implications are profound; microchips are not only crucial for technological advancement but also for national security, as they are vital components in defense technology and various sectors that underpin modern life. A declining position in microchip manufacturing threatens to erode the U.S. economic foundation, leaving it vulnerable to disruptions in supply chains and technological advancements.

Current State of American Microchip Production

Historically, the United States led the world in microchip innovation and manufacturing. However, recent years observed a significant decline in production capacity, primarily due to offshoring to countries with lower labor costs. Currently, the U.S. accounts for only about 12% of the global semiconductor manufacturing capacity. This decline poses a significant risk to both economic stability and technological leadership. The pandemic further exacerbated these challenges, exposing vulnerabilities in supply chains and igniting a call for revitalization of domestic manufacturing capabilities.

Challenges Facing the Microchip Industry Today

Supply Chain Disruptions and Their Impact

The microchip industry has faced unprecedented supply chain disruptions in recent years, highlighted by fluctuations in demand, shortages of raw materials, and geopolitical tensions. These issues have led to delays in production and increased prices for consumers and businesses alike. The COVID-19 pandemic hastened these challenges, revealing the extent to which the global economy relies on a few concentrated suppliers. Remedying supply chain vulnerabilities requires a concerted effort towards diversifying supply sources and increasing local production capacities to mitigate risks associated with dependence on foreign manufacturers.

Technological Barriers to Competitive Manufacturing

Another significant challenge facing the microchip industry is the rapid pace of technological advancement, which poses barriers to manufacturing competitiveness. As technologies evolve, chip designs require increasingly sophisticated fabrication processes that demand substantial capital investment in advanced manufacturing facilities (fabs) and equipment. For American companies to thrive in this environment, it is essential to invest in state-of-the-art facilities that can accommodate new materials and features, such as smaller transistors and complex 3D architectures, while ensuring cost-effectiveness and efficiency.

Policy and Regulatory Obstacles

Government policies and regulations significantly influence the microchip industry. The regulatory landscape can sometimes hinder innovation and growth, particularly in areas such as export controls, labor laws, and environmental regulations. In addition, inconsistent policies across states can lead to inefficiencies and complexities in operations. To revitalizing American microchip production, it is crucial to enact coherent policies that foster innovation, attract investments, and streamline the regulatory environment for manufacturers.

Strategies to Enhance American Microchip Production

Investment in Research and Development

One of the key strategies for enhancing American microchip production is significant investment in research and development (R&D). Dedicating resources to R&D ensures that companies can push the boundaries of technology and maintain a competitive edge. This investment can be achieved through public-private partnerships, encouraging collaboration between government agencies, universities, and private industry. Moreover, enhancing tax credits and grants for R&D can incentivize companies to innovate with the latest technologies, ultimately leading to better production capabilities.

Collaborations Between Government and Industry

A collaborative approach between government and industry stakeholders is essential for rejuvenating the microchip landscape. Initiatives such as the proposed CHIPS Act aim to allocate federal funding to bolster semiconductor manufacturing in the U.S., directing resources to both established companies and startups. Creating industry alliances can streamline the sharing of research, foster innovation, and motivate collective problem-solving for common challenges, ultimately leading to a more robust microchip manufacturing sector in America.

Training and Education for the Workforce

As new technologies emerge, the demand for skilled workers in the microchip industry increases. It is vital to invest in training and education programs that prepare an adequately skilled workforce. Educational institutions, from community colleges to universities, must collaborate with industry experts to design curricula that address the industry’s changing needs. Furthermore, promoting STEM education at the K-12 level can inspire future generations to pursue careers in technology, thus ensuring a sustainable pipeline of talent for the microchip industry.

Innovations Reshaping the Microchip Landscape

Emerging Technologies in Microchip Design

Innovations in microchip design are actively reshaping the industry landscape. Emerging technologies like quantum computing, neuromorphic computing, and advanced AI chipsets promise to enhance processing power dramatically while consuming less energy. These technologies allow for greater efficiencies and capabilities, catering to the needs of advanced applications ranging from cloud computing to biotech innovations. Companies investing in these design methodologies will position themselves at the forefront of the microchip market, acquiring a competitive advantage over traditional manufacturing processes.

Adoption of Sustainable Manufacturing Practices

Sustainability in manufacturing is becoming increasingly pivotal in all industries, and microchip manufacturing is no exception. Companies are being called upon to minimize their environmental impact by adopting sustainable practices, including waste reduction, energy-efficient processes, and utilizing renewable resources. Implementing green manufacturing methods not only preserves the environment but also appeals to a growing market of eco-conscious consumers and investors alike.

Future Trends in Microchip Applications

The applications of microchips are rapidly expanding beyond traditional roles, poised to revolutionize industries such as healthcare, transportation, and smart infrastructure. For instance, the integration of microchips in medical devices allows for enhanced diagnostics and personalized healthcare solutions. Likewise, the automotive industry is seeing the rise of chips enabling autonomous driving features. Keeping pace with these trends ensures that American microchip manufacturers can capitalize on growing market demands and remain competitive on a global scale.

Measuring the Success of Microchip Initiatives

Performance Metrics for Industry Growth

To ascertain the effectiveness of initiatives aimed at revitalizing American microchip production, appropriate performance metrics are essential. Key indicators may include production capacity, revenue growth, levels of R&D investment, workforce numbers, and supply chain efficiency. Tracking these metrics will help gauge the industry’s health, enabling stakeholders to make informed decisions on future investments and policies aimed at fostering growth.

Case Studies of Successful Microchip Projects

Examining successful case studies can provide insights into best practices and approaches that flatten the learning curve for other entities. For instance, the establishment of successful semiconductor manufacturing plants in states like Arizona and Texas exemplifies how government support, industry collaboration, and a skilled workforce can come together to revitalize production capabilities. Such projects could serve as templates for similar efforts across the nation, propelling growth and innovation in the sector.

Long-term Projections for American Competitiveness

Long-term projections for American competitiveness in the microchip industry hinge on the strategic initiatives undertaken in response to current challenges. With adequate investment, collaboration, and innovation, the nation can potentially regain a leadership position in microchip manufacturing. Forecasts suggest that by bolstering production capabilities domestically and staying ahead of technological advancements, the U.S. can establish a self-sufficient and secure microchip industry that meets both economic and national security needs.